|

CONTACT IMS TODAY! Our TEAM is ready to help you select the right products and services for your application. (888) 344-3842

Specializing in Precision Machine Tool Products, Services, and Solutions for Over 15 Years!

|

MACHINE TOOL MAINTENANCE Are you Preventive or Reactive when it comes to your machine tool maintenance? IMS knows how important routine and annual preventive maintenance is for maintaining a reliable, accurate, and repeatable machine tool. Our Machine Tool Maintenance (MTM) programs mitigate machine failures and unscheduled downtime; moreover, meet Original Equipment Manufacturer (OEM) specifications, and comply with ISO 9000, ISO 9001, ISO 13485 and AS 9100 Quality Management Systems (QMS), as well as ASME B5.54, ASME B5.57, ISO 230-4, or JIS B standards and practices to ensure optimum performance of your machine tools.

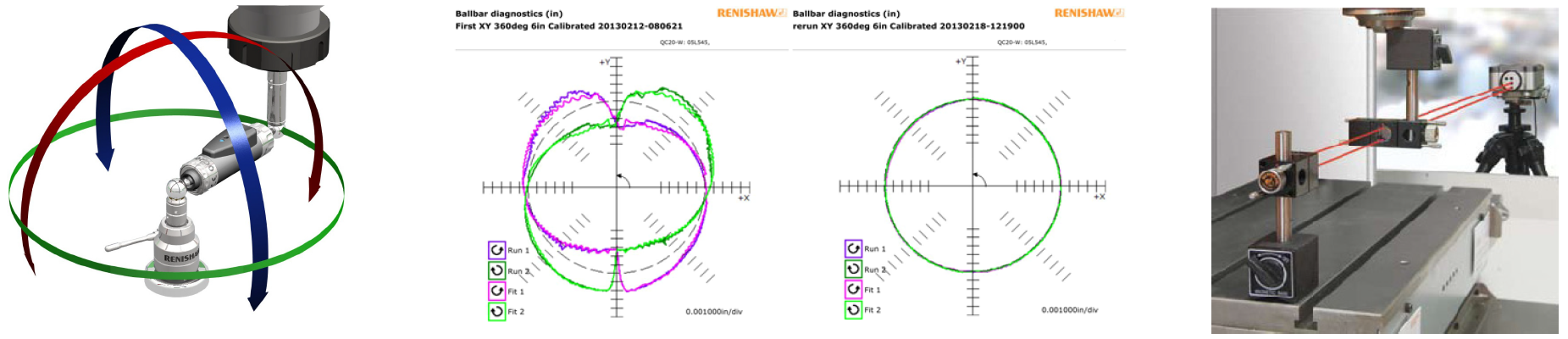

As a brief summary, IMS MTM programs provide the necessary technical resources to safely carryout preventive maintenance tasks onsite at your facility that include but are not limited to cleaning, inspecting, lubricating, minor calibrations, minor repairs, software backups, reports, and recommendations. IMS calibrates manual and CNC machine tools striving to achieve OEM specifications, or best possible settings within reason, until major calibrations and/or repairs are completed. Unless otherwise specified, major calibrations and/or repairs will be addressed on a time and materials basis, and scheduled at a later date convenient to both parties. Our team of experts utilize state-of-the art diagnostic equipment to evaluate your machine tool’s geometry error. For example, a Renishaw QC-20W wireless ballbar system is used to perform dynamic circular tests of numerically controlled and computer numerically controlled machine tools to analyze your machine’s performance in accordance with either ASME B5.54, ASME B5.57, ISO 230-4, or JIS B standards. Ballbar data is recorded using Renishaw Ballbar 20 software that complies with the aforementioned standards which specify methods of testing and evaluating bi-directional circular deviation, the mean bidirectional radial deviation, the circular deviation and the radial deviation of circular paths that are produced by the simultaneous movements of two linear axes, consequently producing a detailed plot of errors, including but not limited to, circularity, backlash, reversal spikes, lateral play, cyclic error, servo mismatch, squareness, scaling mismatch, scaling error, and cyclic pitch. IMS evaluates the error plot to determine if the errors can be calibrated through routine mechanical adjustments or servo tuning, and if discovered that major calibrations and/or repairs are required to compensate for worn and/or damaged parts, IMS will submit recommendations to the client accordingly. IMS also offers linear and nonlinear calibration services using a state-of-the art Renishaw XL-80 Laser Interferometer System. These services are not included in most MTM programs, therefore, additional funding may be required. The most common service that IMS provides is Linear Displacement Error Evaluation & Compensation (LDEE&C) that produces a detailed plot of your machine’s positional error which can be compensated through the control for optimum positional accuracy along the entire axis of travel. Contact IMS to schedule your walk-through today.

|